THE EVOLUTION AND MATURITY OF AUTOMOBILE RADIATOR LAYOUT

Early car engines had different forms of radiators, which fully reflected the designer's mind. The picture below is a water-cooled radiator of an early car. It consists of a set of light pipes. Since it is located at the rear of the vehicle, it almost completely relies on the natural convection on the air side.

In later car designs, the car radiator already has a secondary surface enhanced heat transfer feature. The picture below is a Mercedes-Benz car in 1899. The vehicle radiator is wrapped in the front of the car, making full use of the oncoming airflow for cooling.

After entering the 20th century, classic radiator arrangements appeared. The radiator is arranged at the front of the car, making full use of oncoming air for cooling. The heat exchange core is located between the two water chambers, and this arrangement continues to this day.

But this does not mean that there will be no development in the later period. The understanding of the heat transfer process in the engine has been greatly improved, so that the design of the engine cylinder head can be more than an order of magnitude higher than the earlier heat transfer. The system components are more compact. Although the basic system layout has not changed much, in recent years there has been a shift to electronic control to improve the response to transient operating conditions, engine emissions and energy management.

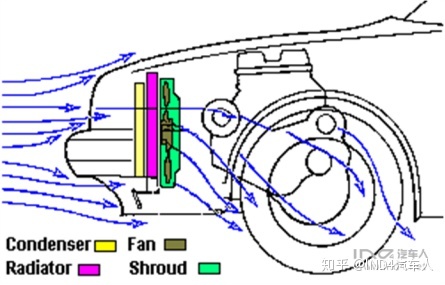

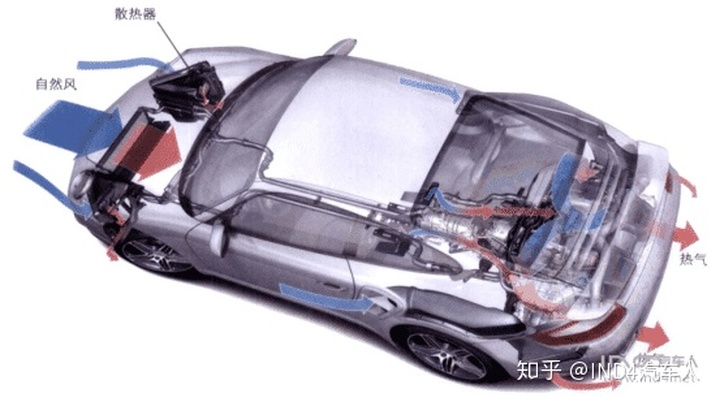

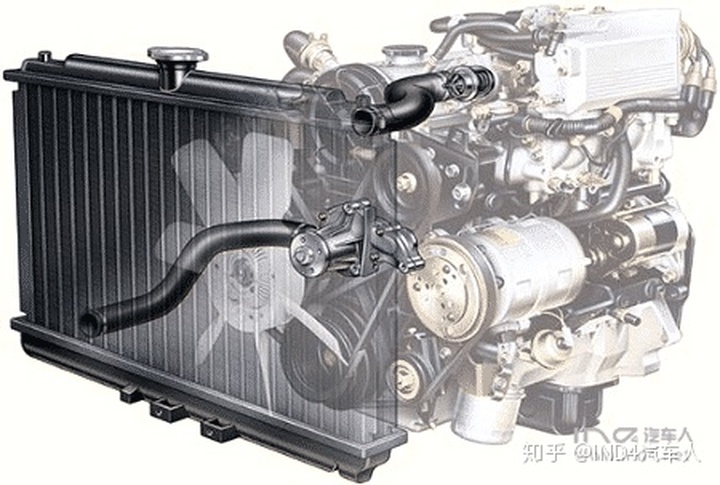

The radiator, condenser, intercooler, and cooling fan of modern cars form a front-end cooling module, which is arranged in the front of the car. Component matching and ventilation design have become quite complicated and become a specialized branch of automobile design.

In order to make full use of the oncoming wind and avoid the occlusion of the condenser, Porsche designers split the radiator in two and moved it to both sides of the front (see the picture below).

Porsche 911GT3 radiator layout

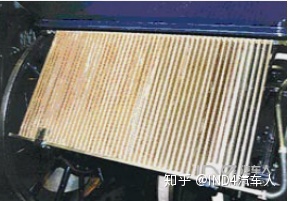

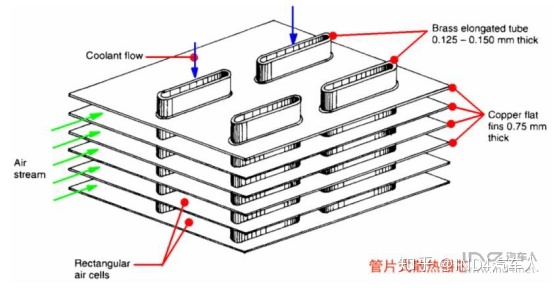

The core of the tube-fin radiator is composed of many cooling tubes and fins. The cooling pipe is welded between the upper and lower water chambers as a channel for cooling water. The heat sink is sleeved outside the cooling pipe to increase the heat exchange area. When the air blows through the core, the water flowing in the tube is cooled (see figure below). The heat sink is generally made of copper with very good heat conduction, and the cooling tube is made of brass with relatively high strength. Then they are joined together by soldering. The cross-section of the cooling tube is made oblate to reduce wind resistance and increase the heat dissipation area; when the water in the tube freezes, the flat tube can withstand expansion and deformation to avoid rupture. The tube-fin radiator has good strength, high pressure resistance and vibration resistance, but the manufacturing process is more complicated and the cost is high.

In 1904, Royce, an engineer in Manchester, England, built his first batch of cars, which were small two-seater cars with only 10 horsepower. The British aristocrat Rawls was very interested in it when he heard about it, and soon went to Manchester to meet with Royce, and the two decided to jointly form the Rolls Royce Motor Company.

The first tube-fin car radiator is installed in the front of the car. The radiators of this period were all exposed. As part of the front of the car, the water chamber and the water tank cover were also made of brass. They were bright and shiny, which was a good decoration. The "R" trademarks stacked together are pasted on the water chamber (see the picture below).

The oldest known surviving Rolls-Royce in the World, The 1904 Paris Salon and 1905 Olympia Motor Exhibition Display Car,1904 Rolls-Royce 10hp Two Seater

In 1908, Ford introduced a cheap Model T car. With the assembly line production method invented by Ford, automobile radiators have also entered the era of assembly line production, with one radiator every ten seconds. By the end of production in 1927, the Model T had set a production record of 15 million.

T type car radiator layout

The layout and structural features of the radiator of the Ford Model T and the production process are very similar to those of modern cars. The author recommends everyone to watch the documentary film of Ford Model T and feel the surging atmosphere of big industry.

Arrangement of radiator of T-car

T-type car assembly line

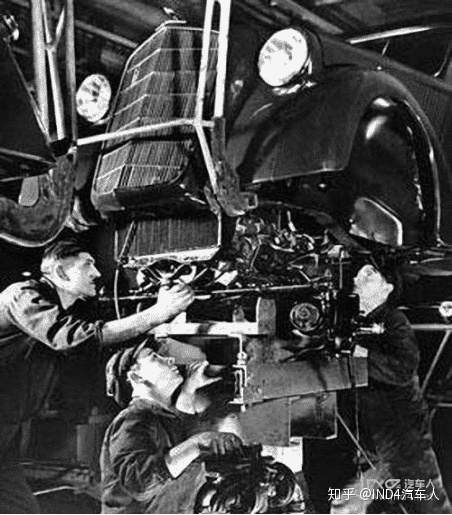

The 1930s and 1940s were an important period for the maturity of automobile radiators. It is basically unified into a longitudinal flow fully enclosed structure, and a tube-sheet copper brazing core. It is arranged in the engine compartment and is well protected. The design method and manufacturing process of the radiator have also been gradually improved. The automobile radiators in the initial period of my country's automobile industry are also of this type.

In the Buick car production line in the 1930s, the radiator was first installed on the chassis

The Willis Jeep, which was all the rage during World War II, had almost the same radiator structure and vehicle layout as the Beijing 212 30 years later.

Willis Jeep's radiator Beijing 212's radiator

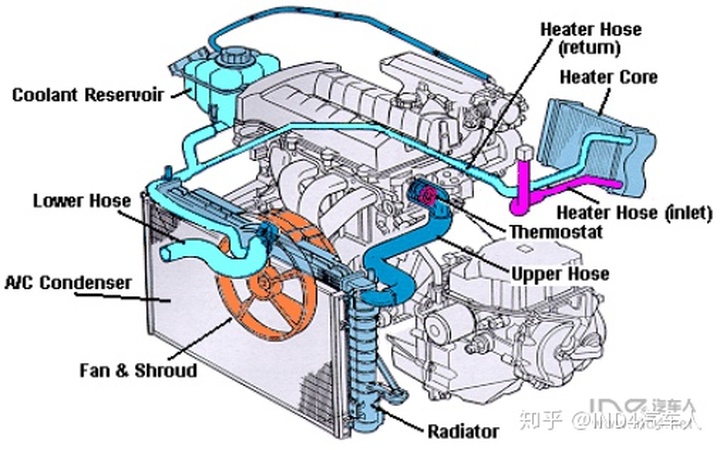

In the beginning, car radiators were equipped with water chambers up and down, and cooling water flowed from top to bottom. Until the early 1960s, with the development of car design, cross-flow radiators appeared.

The water chamber of this kind of radiator changes from top to bottom to left to right, and the cooling water changes from vertical flow to cross flow. The cross-flow radiator can effectively reduce the height of the engine hood, expand the field of vision, reduce the wind resistance, and improve the freedom of the vehicle's styling. Compared with the longitudinal flow radiator, the effective area of the front of the core can be increased by 10%, thereby increasing the size of the fan, obtaining more windward area, and allowing the air to pass more smoothly. In order to make up for the lack of water storage capacity of the cross-flow radiator, a liquid storage tank is installed near the upper water chamber.

Today's cars, basically trucks follow the vertical flow structure, and cars use the cross flow structure. The difference between trucks and car radiators is also growing.

Click to start!

Click to start!