Our company are a high-tech enterprise specializing in the research, development, production, and sales of oil coolers. We are committed to providing efficient and durable thermal management solutions to customers worldwide. Leveraging **XX years** of industry experience and advanced production technology, our products are widely used in **automobiles, construction machinery, marine, wind power, industrial equipment, and other fields. Our superior cooling performance and consistent quality have earned us market trust.

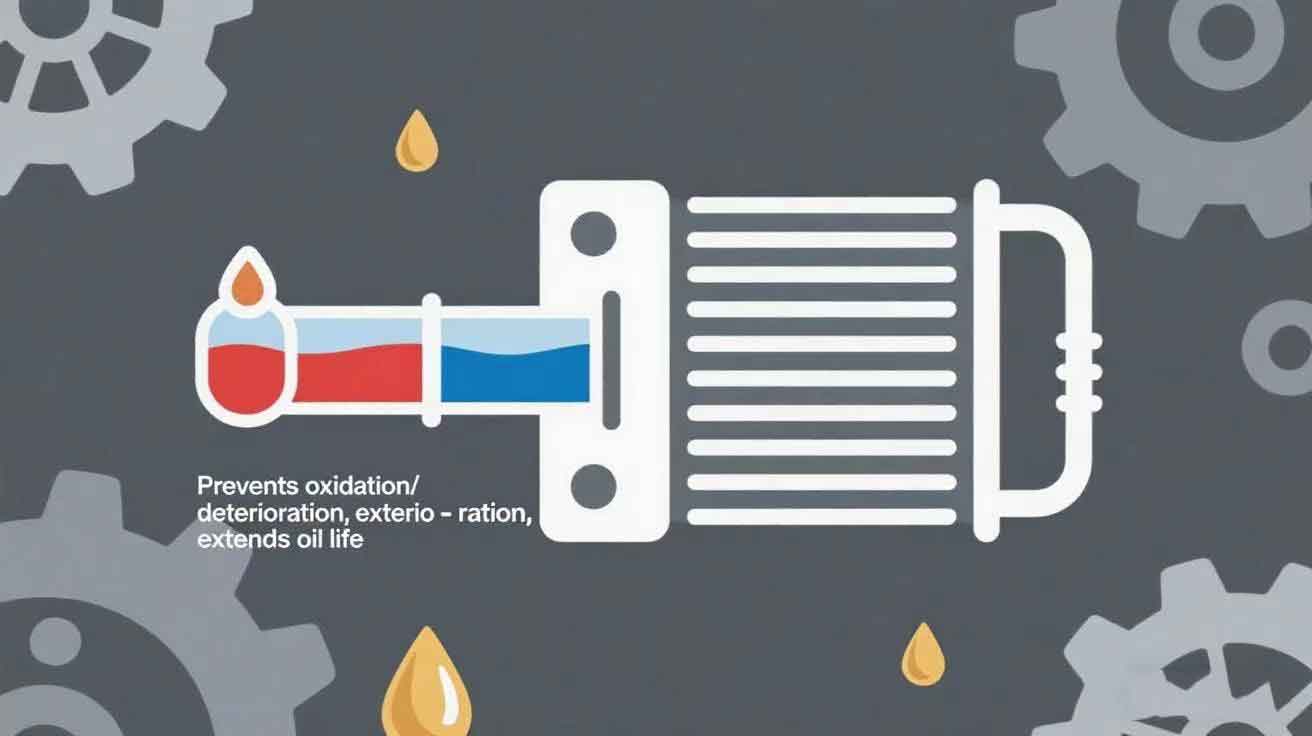

An oil cooler is a heat exchange device used to cool lubricating oil, hydraulic oil, or transmission oil. It is widely used in automobiles, construction machinery, ships, wind power generation, industrial equipment, and other fields. Its core function is to maintain the oil at the optimal operating temperature through efficient heat dissipation, ensuring stable operation and extending the service life of the equipment.

Oil coolers, if categorized by cooling method, can be divided into air-cooled, water-cooled, and plate-fin oil coolers.

Dissipate heat through air flow, have a simple structure, and are suitable for mobile equipment (such as automobiles and construction machinery)

Utilize circulating cooling water for heat exchange, offering high efficiency and are commonly used in stationary applications such as ships and industrial equipment.

Combine air and water cooling, using a multi-layered heat sink structure, offering a large heat dissipation area and a lightweight design.

Oil coolers can be categorized by structure into shell and tube oil coolers, plate oil coolers, and aluminum/stainless steel oil coolers.

The oil flows through tubes and is cooled externally by air or water. They are high-pressure resistant and suitable for heavy-duty equipment.

They consist of multiple layers of stacked metal plates, with oil and cooling medium flowing alternately. They offer high heat exchange efficiency and a compact size.

Aluminum alloy is lightweight and corrosion-resistant, while stainless steel is suitable for high-temperature and high-pressure environments.

An oil cooler reduces oil temperature through heat exchange. The basic process is as follows

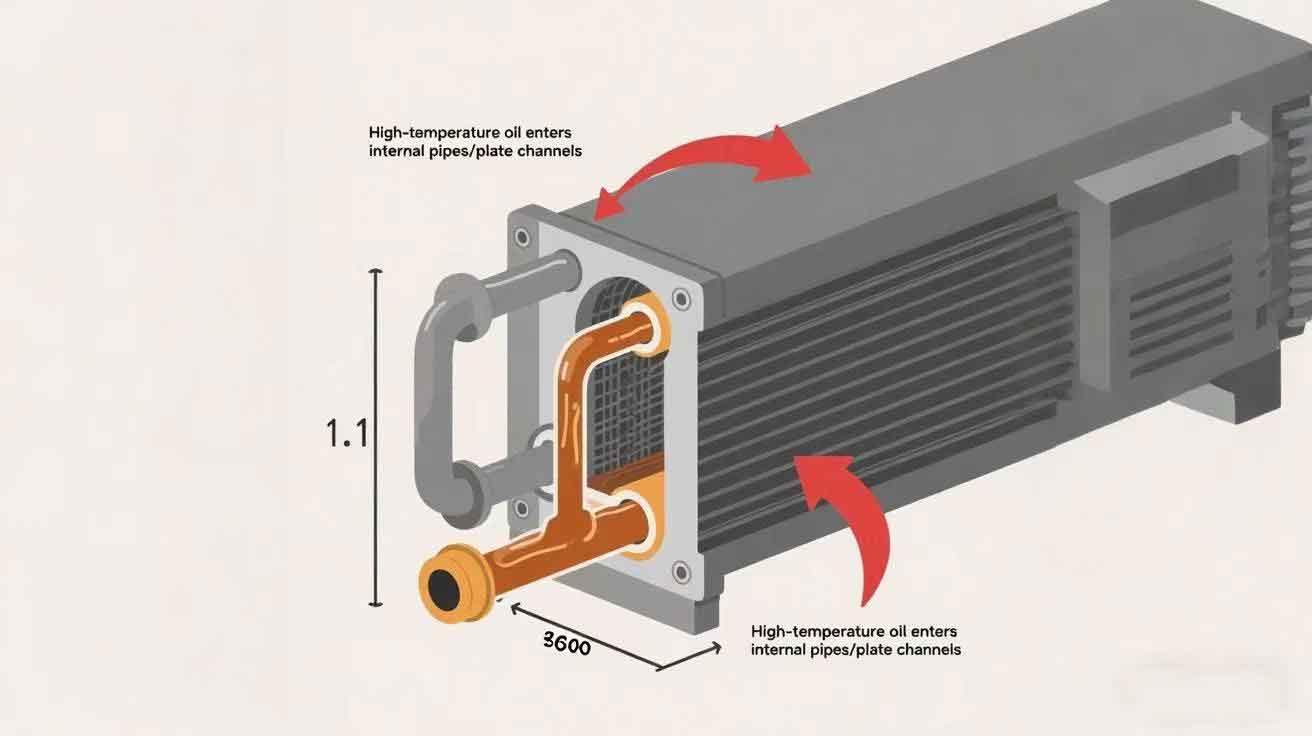

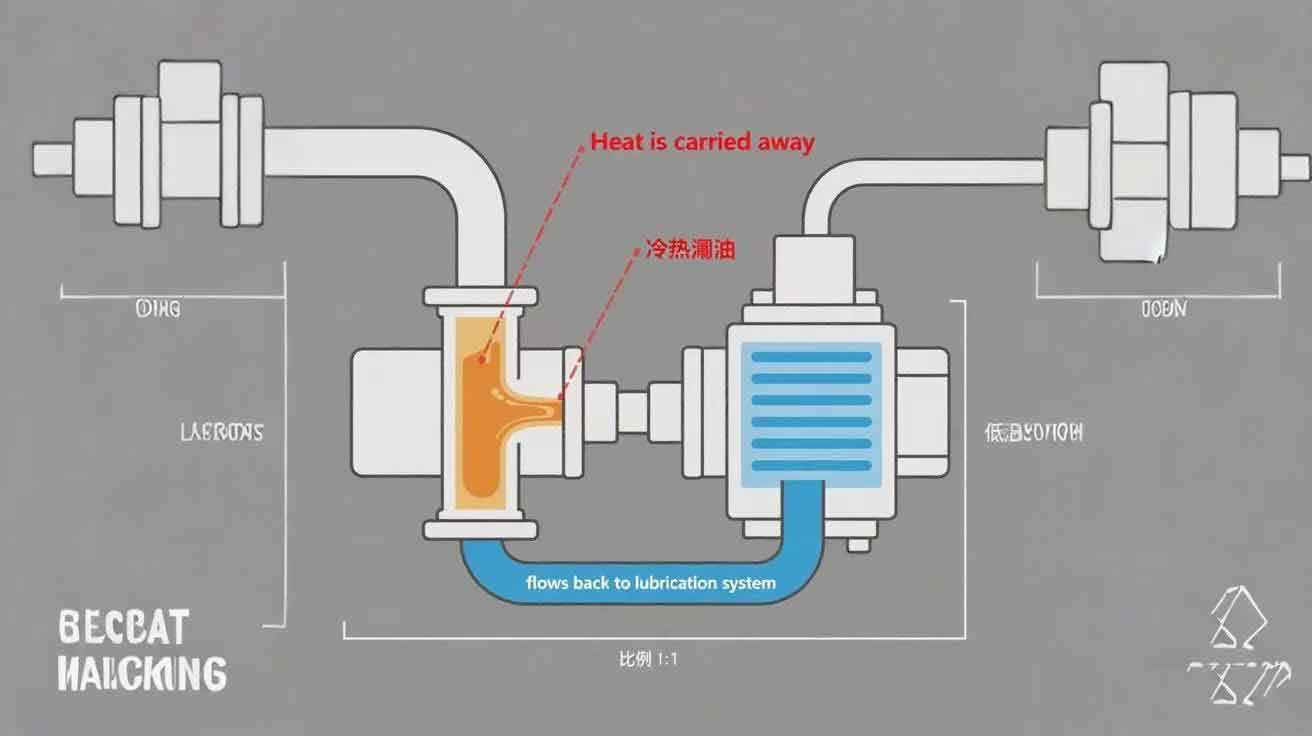

High-temperature oil enters the cooler’s internal pipes or plate channels.

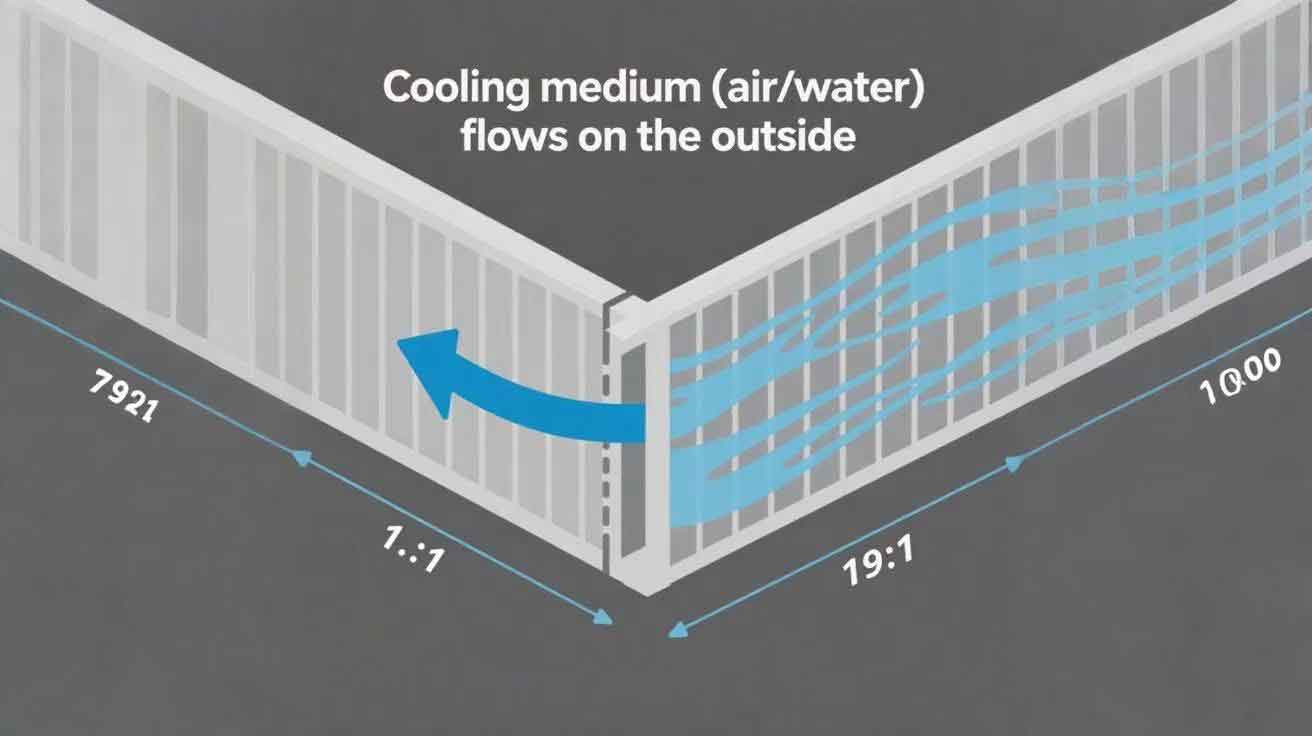

A cooling medium (air/water) flows outside, absorbing heat from the oil.

Heat is removed, and the oil, after cooling, returns to the equipment’s lubrication system, maintaining a stable viscosity.

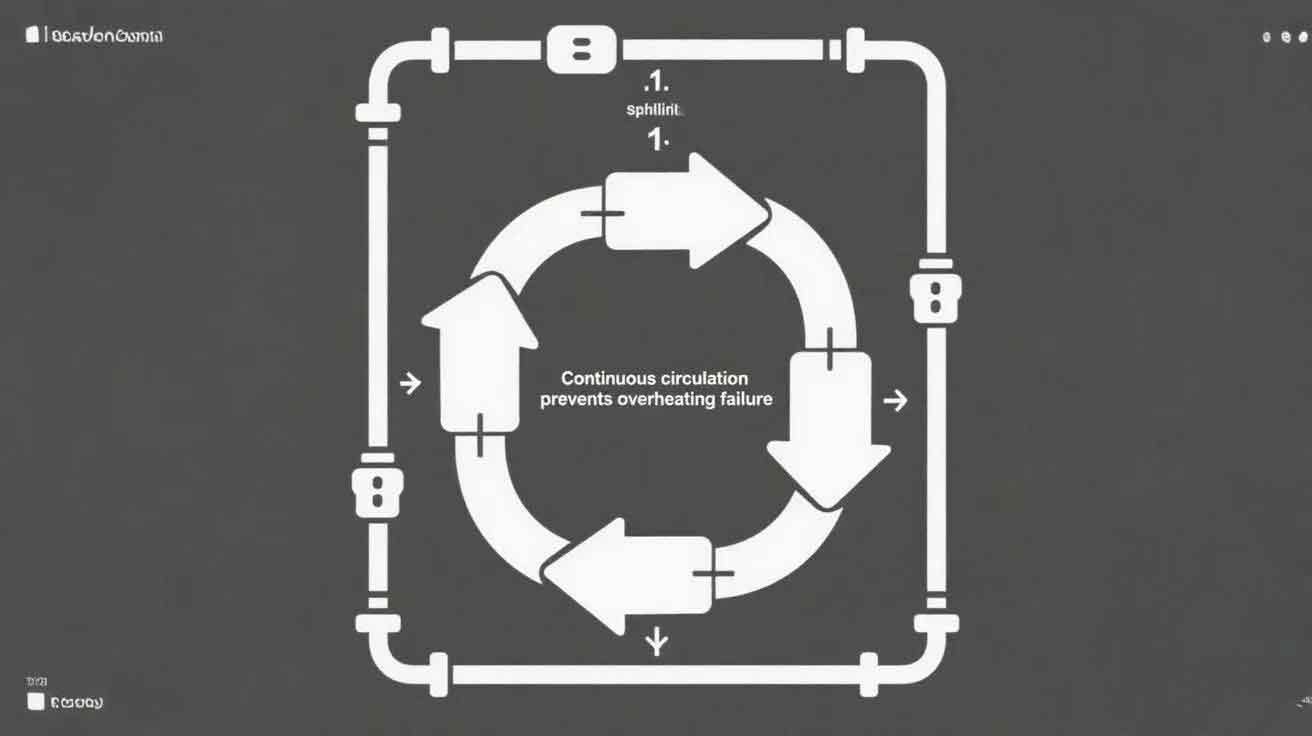

Continuous circulation prevents equipment failure due to excessive oil temperature.

Lowers equipment operating temperatures, reduces energy consumption, and increases power output.

Prevents problems such as seal aging and hydraulic system failure caused by high temperatures.

Lowers equipment operating temperatures, reduces energy consumption, and increases power output.

1.Flow and Heat Dissipation Requirements: Select the heat dissipation capacity that matches the oil flow rate and operating temperature.

2.Installation Space: Air-cooled oil coolers are suitable for well-ventilated environments, while water-cooled oil coolers require a cooling water circuit.

3.Pressure and Corrosion Resistance: Choose stainless steel for high-pressure environments, and aluminum with rust-resistant coating for corrosive environments.

4.Maintenance Ease: Easy-to-clean designs reduce long-term operating costs.

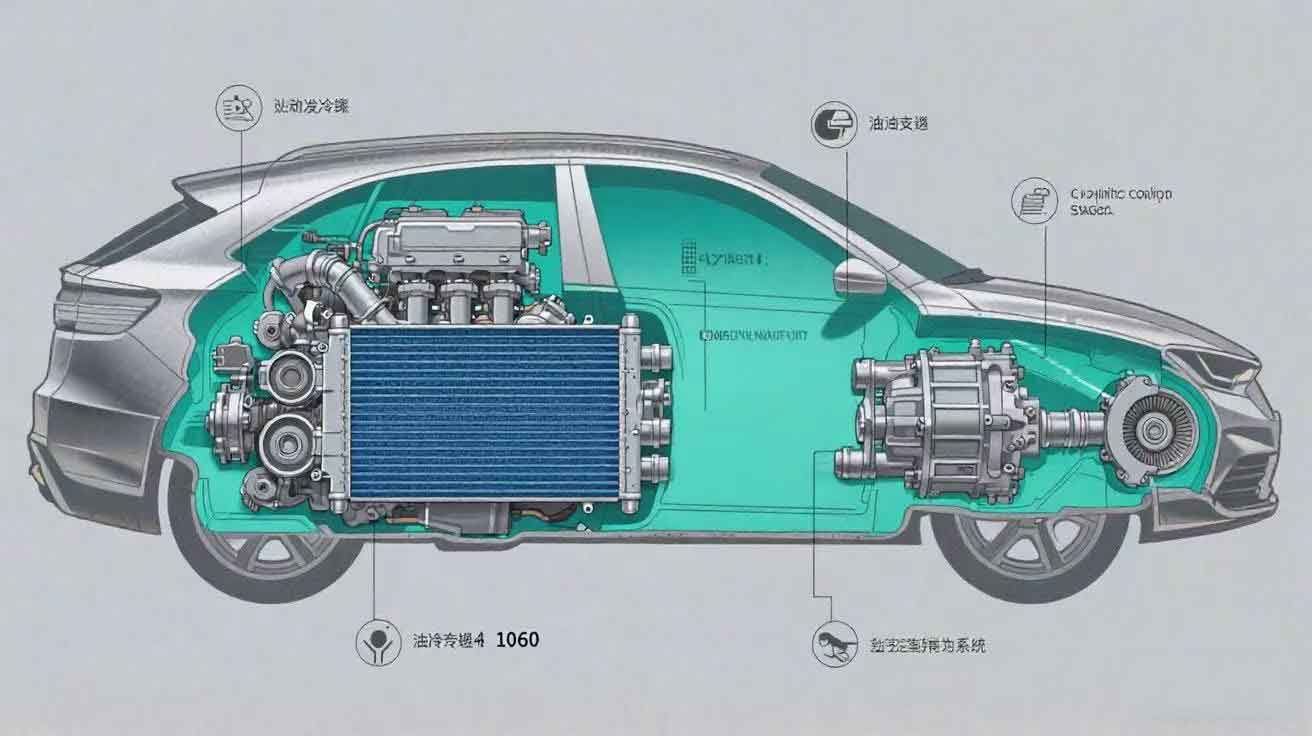

Engines, Transmissions, Turbocharger Systems | Cools lubricating oil and improves power performance

Excavators, Loaders, Hydraulic Systems | Prevents hydraulic oil from overheating and ensures stability |

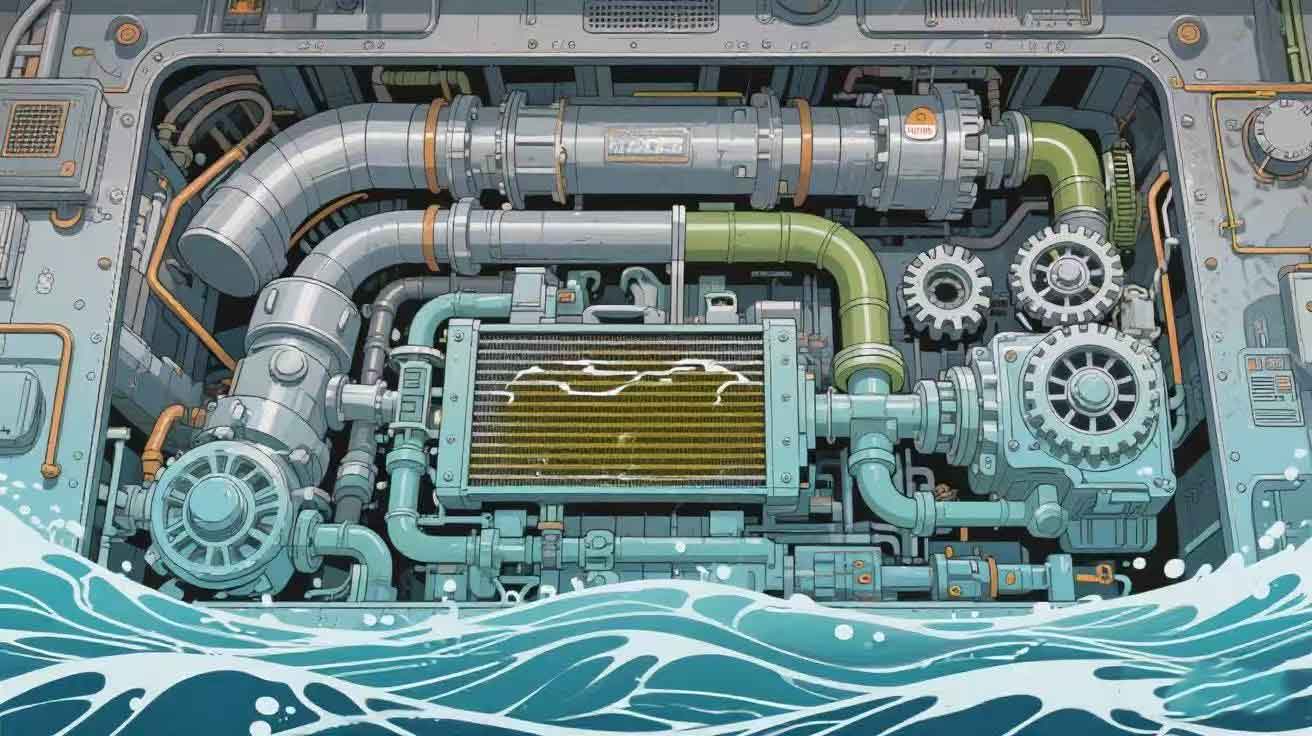

Engines, Gearboxes, Hydraulic Systems | Seawater/Freshwater Cooling for High-Salinity Environments |

Gearboxes, Hydraulic Pitch Systems | Reduces friction loss and extends maintenance cycles |

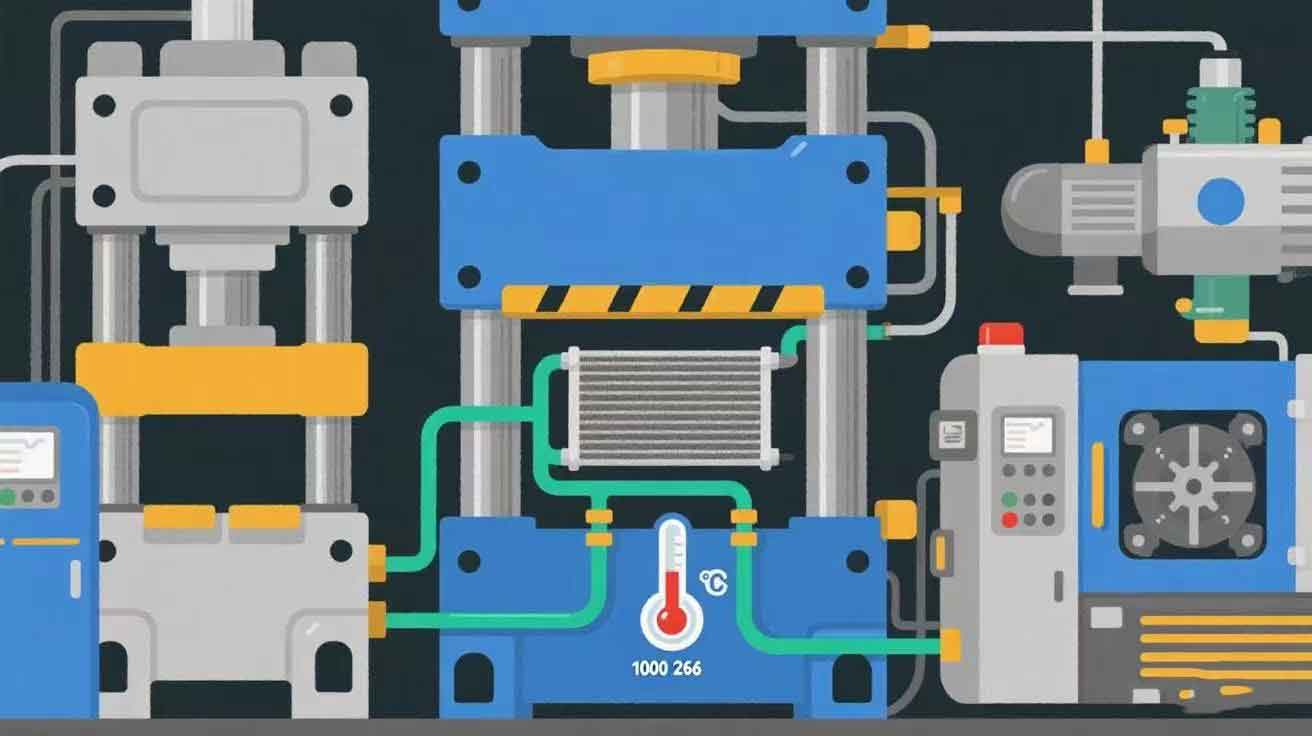

Hydraulic Presses, Air Compressors, Injection Molding Machines | Stabilizes oil temperature and improves production efficiency |

1.Efficient Heat Dissipation**: Optimized flow channel design improves heat exchange efficiency by over 20%.

2.Durable and Reliable**: Made of aircraft-grade aluminum alloy/stainless steel, they are resistant to high pressure and corrosion.

3.Customization**: Customizable to meet specific requirements, including size, interface, and heat dissipation power.

4Globally Certified**: Qualified by ISO 9001, IATF 16949, and other quality management systems.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.